Architecture & Design Veneer Specification

Specifying wood veneer for architects and designers.

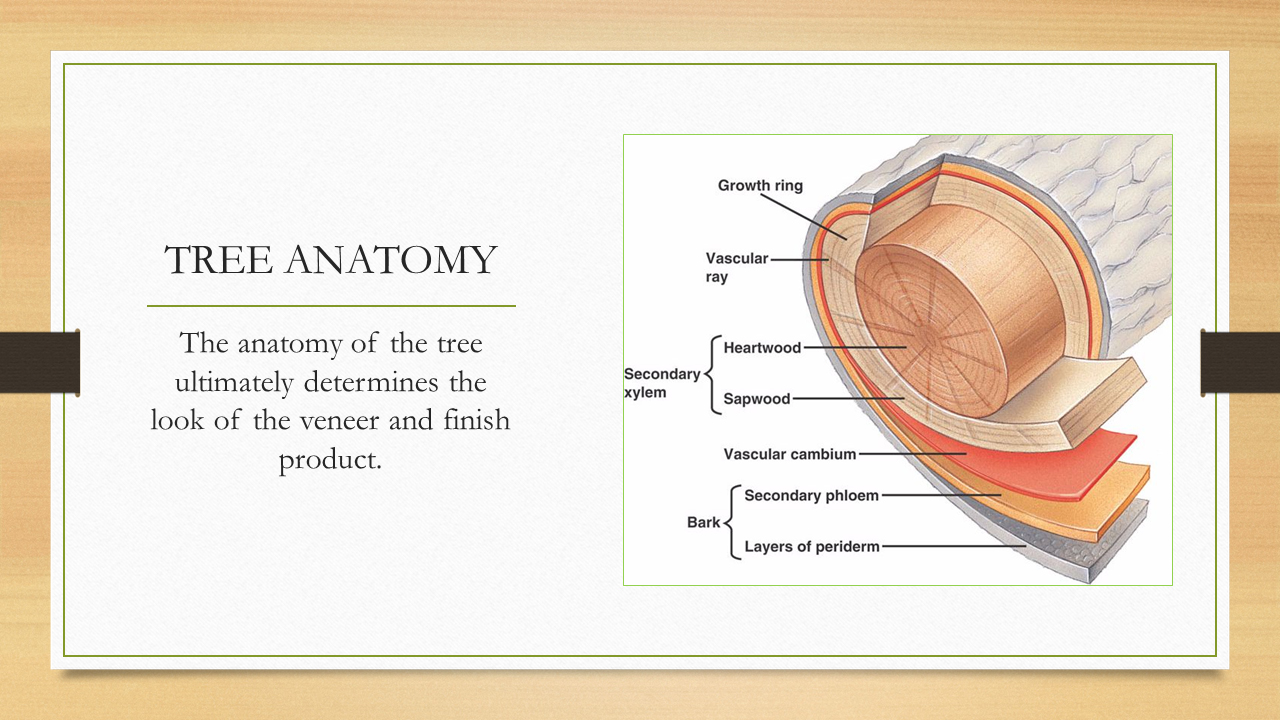

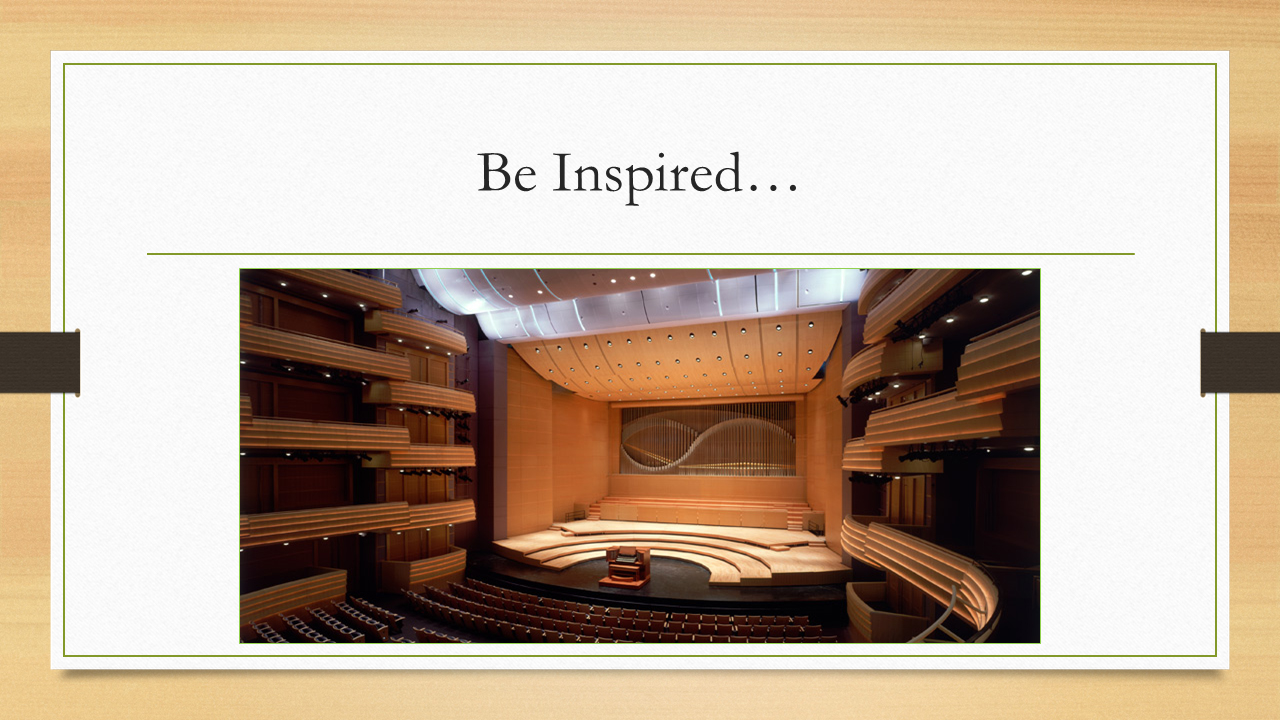

Every tree is influenced by its natural surroundings making it distinctly unique. The use of wood veneer in your project gives architects and designers great freedom to create a final product that cannot be replicated! Within a species there can be thousands of variations of color, grain & figure. This can make the selection/specification process difficult for architects and designers, but we are here to help guide you through the process to achieve the final desired aesthetic.

How can we help?

The Veneer Source is proud to offer our A&D clientele with CEU Courses for IIDA credit, lunch & learn presentations, provide custom finish panels and guidance through the specification process.

Specification Process:

Contact your TVS Representative to go over project specifications and determine species that are a good fit for your needs.

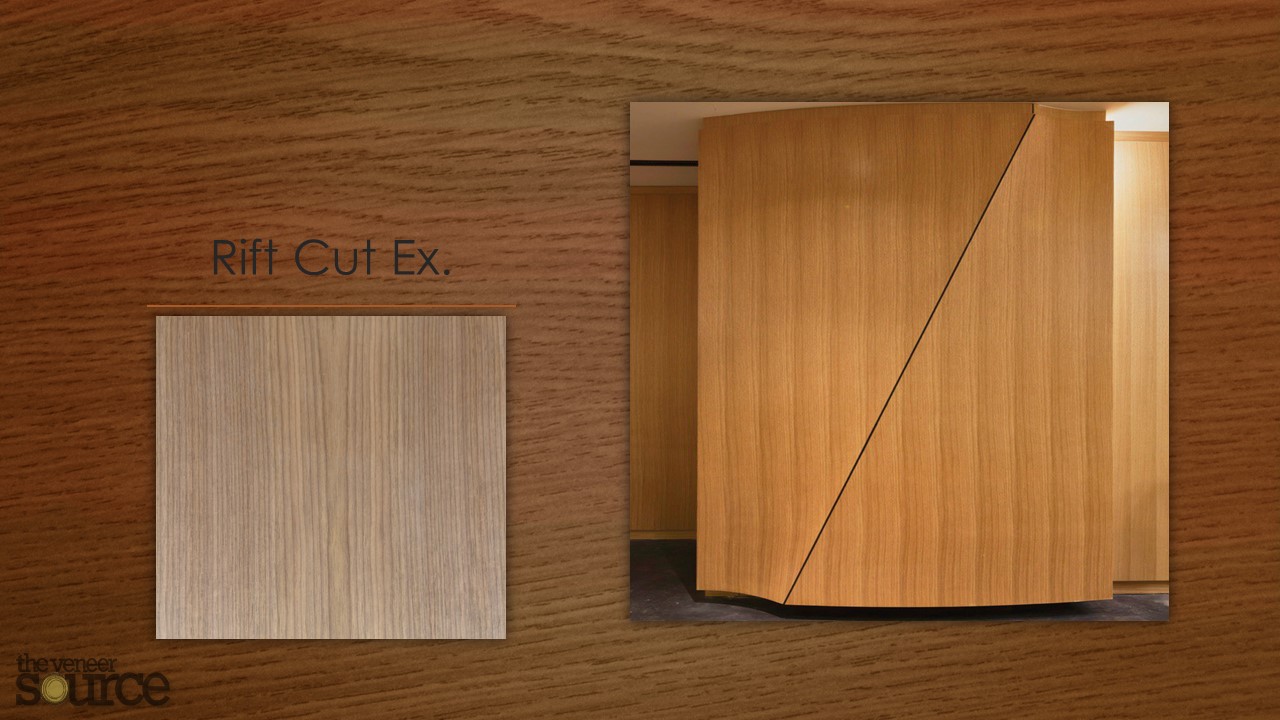

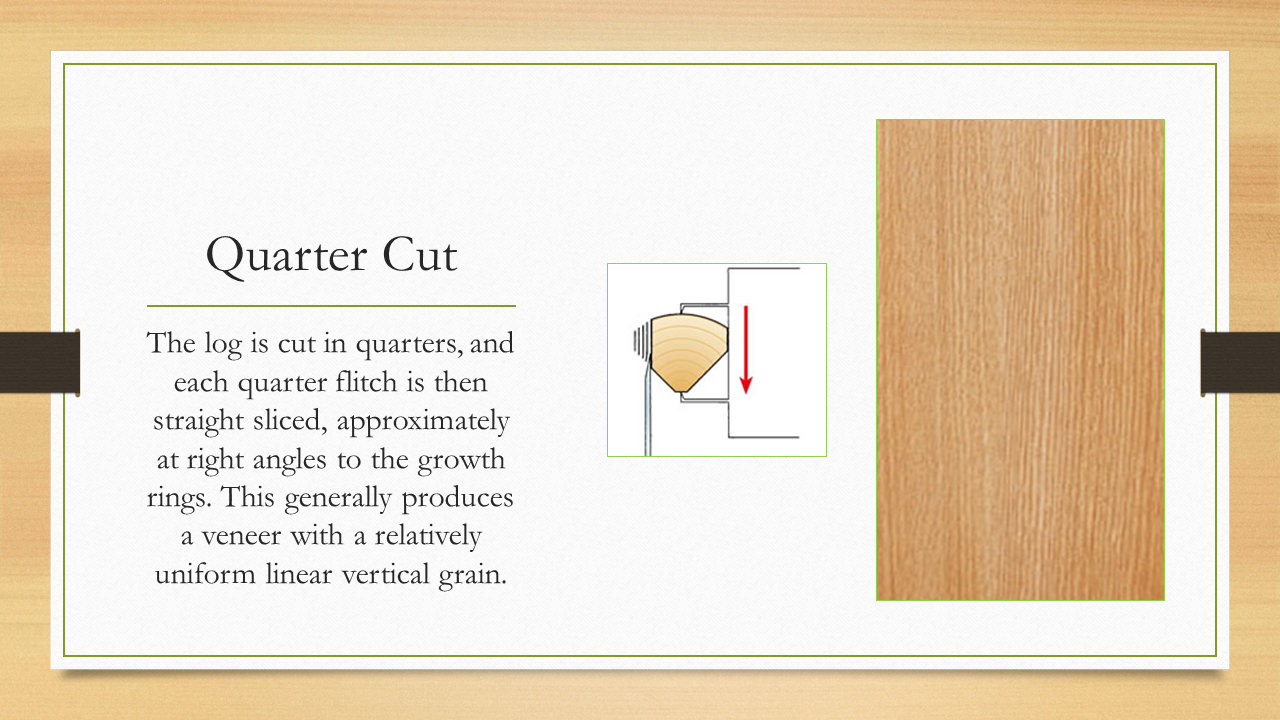

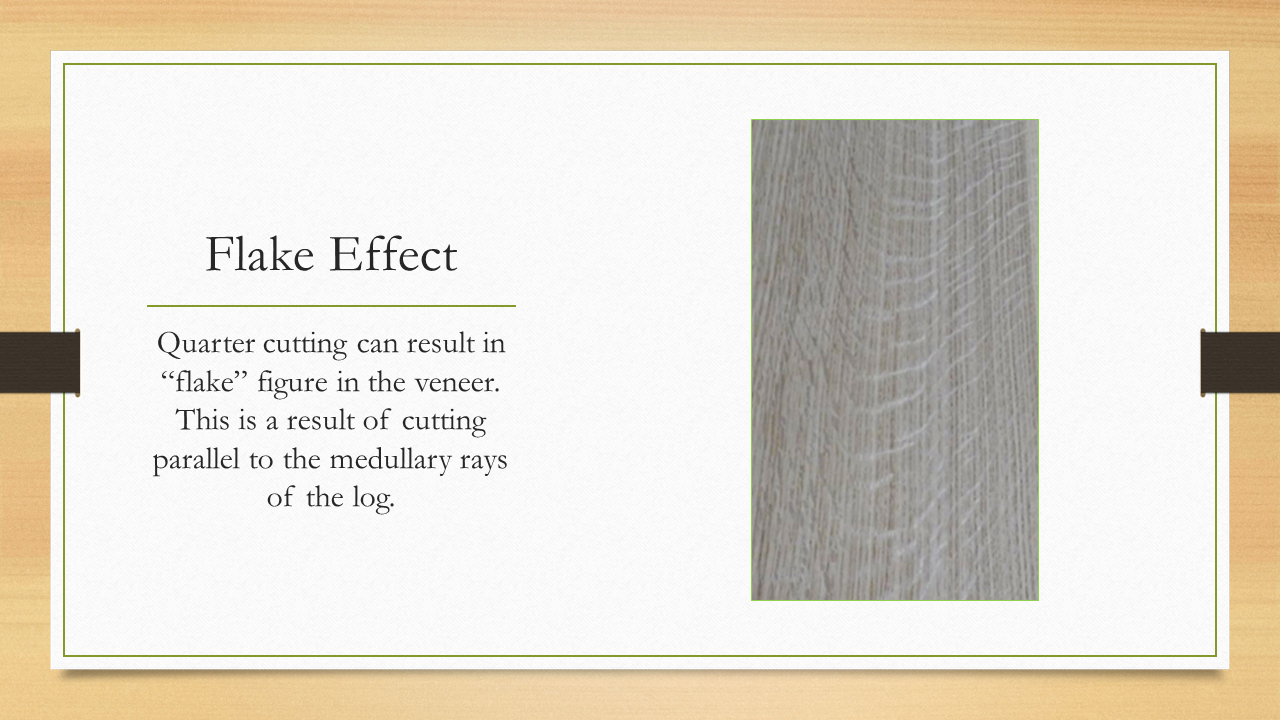

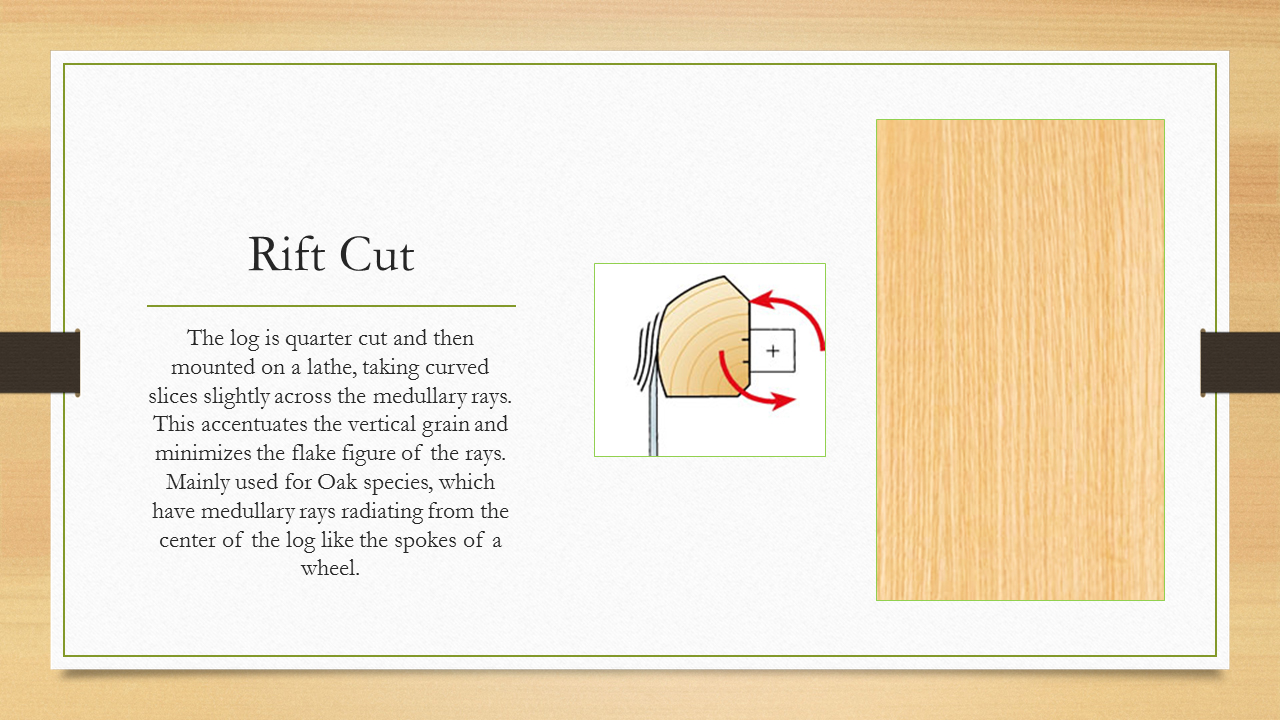

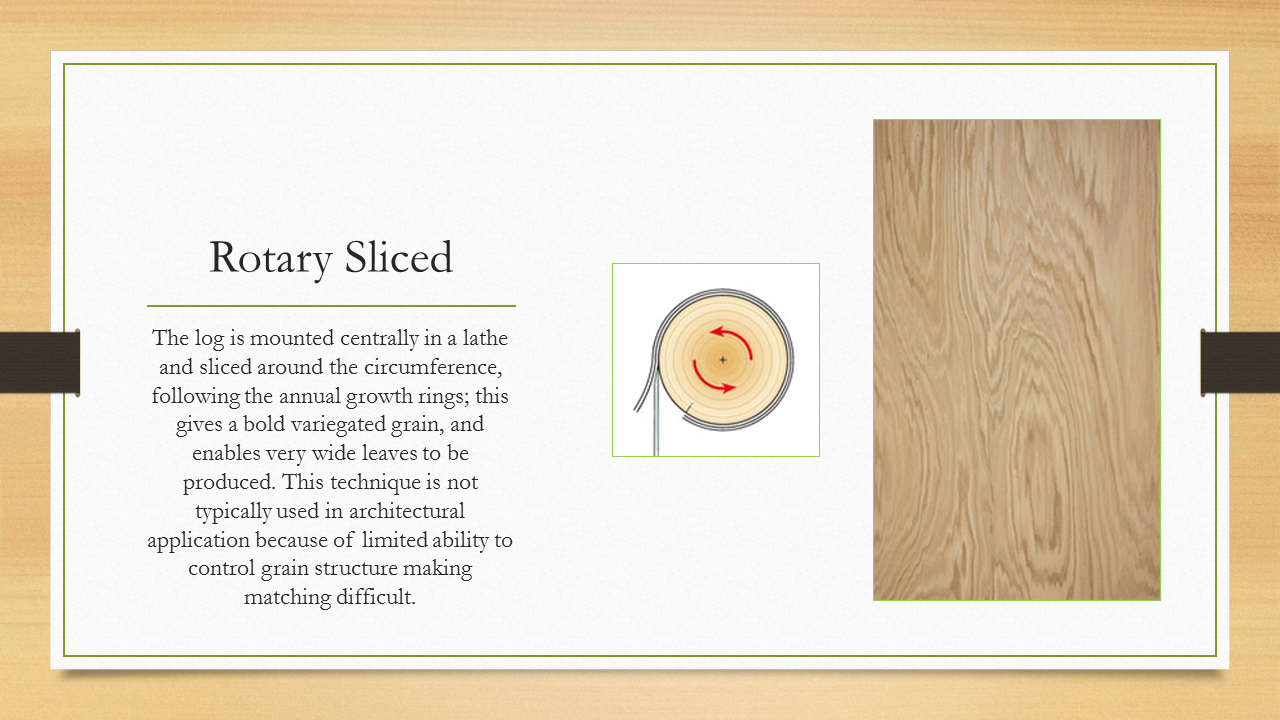

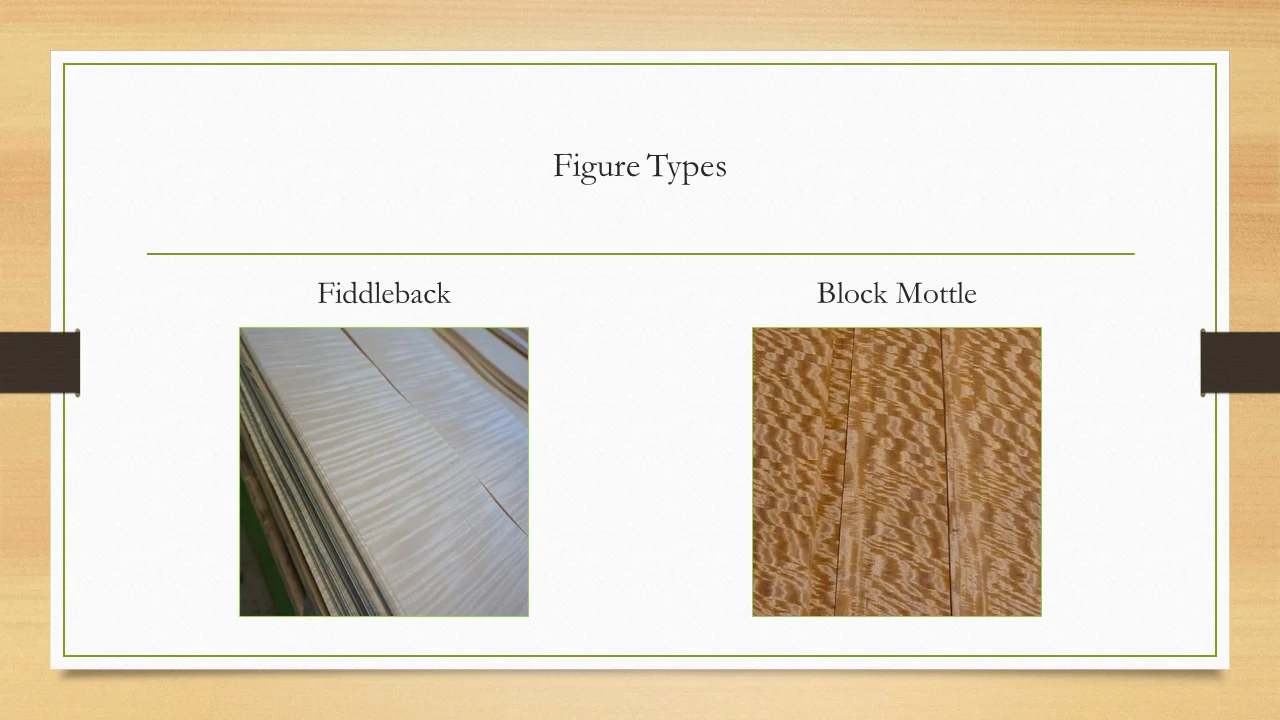

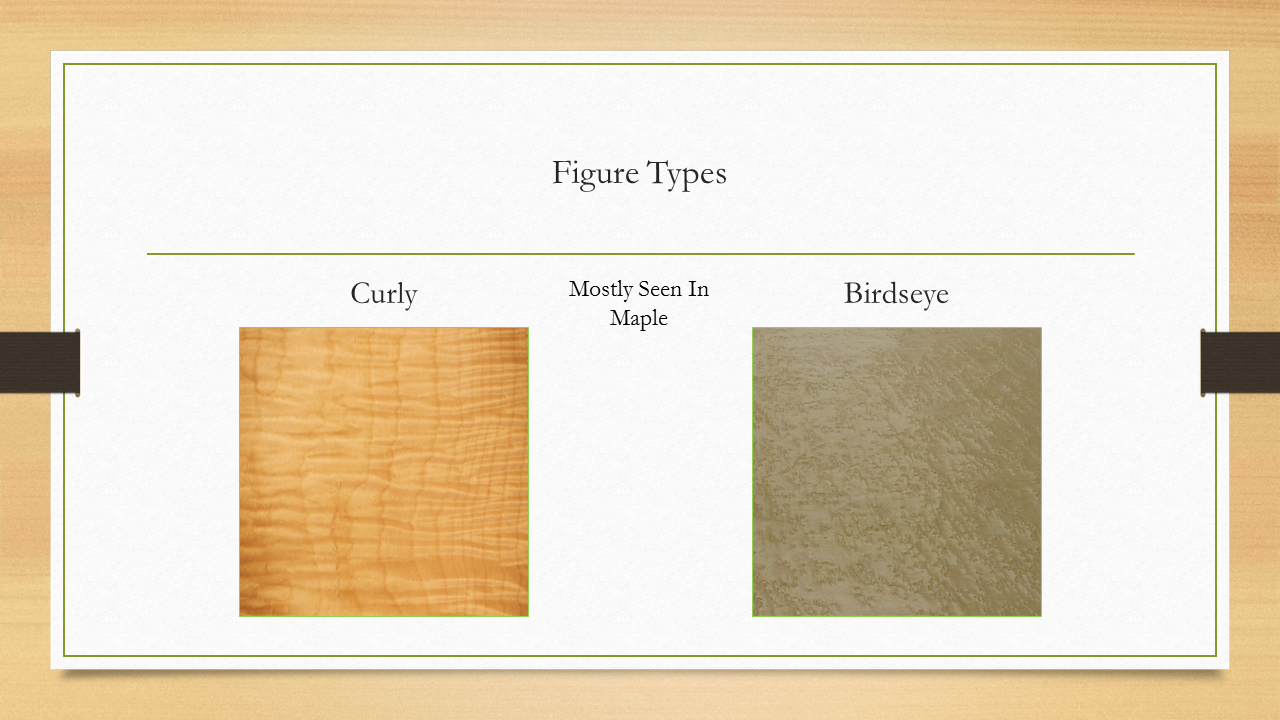

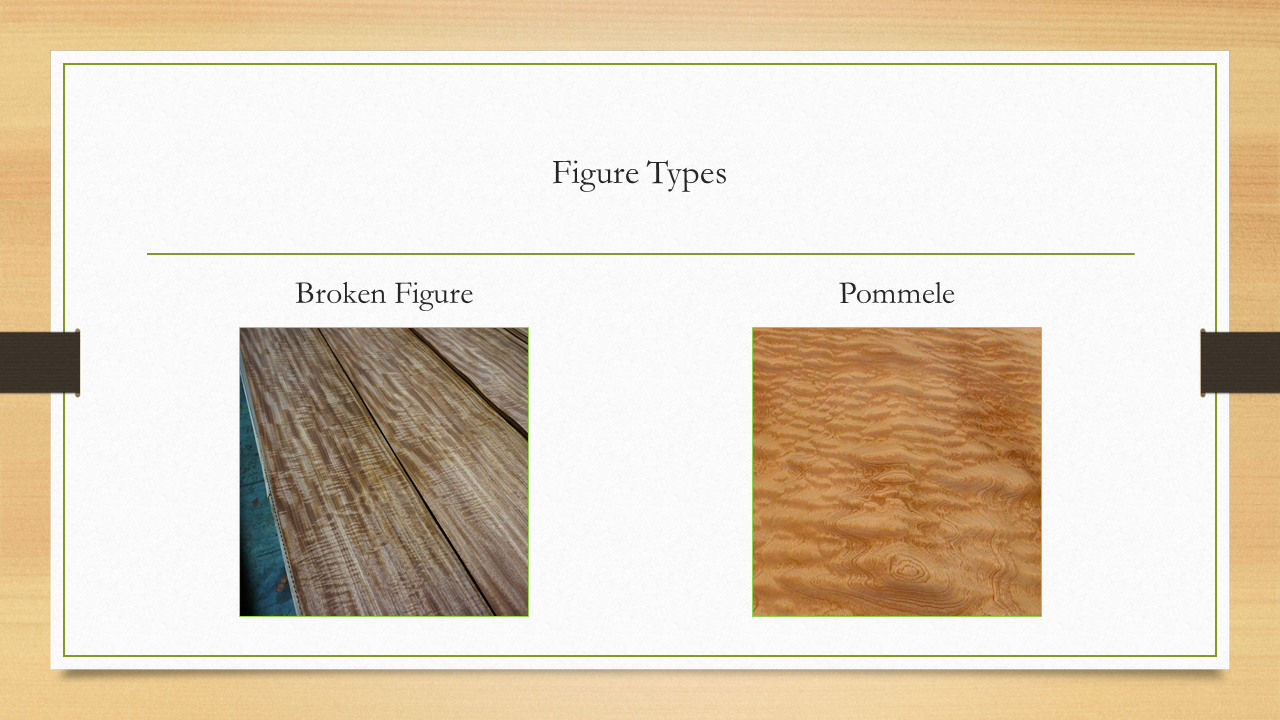

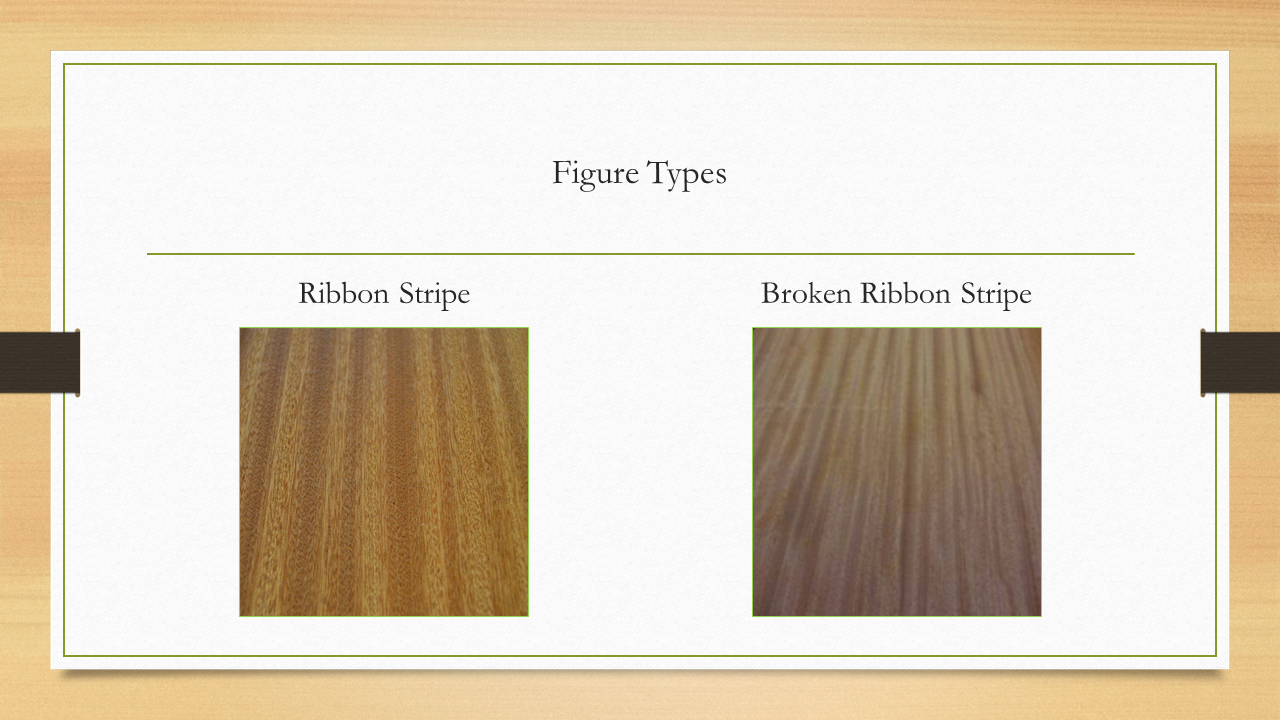

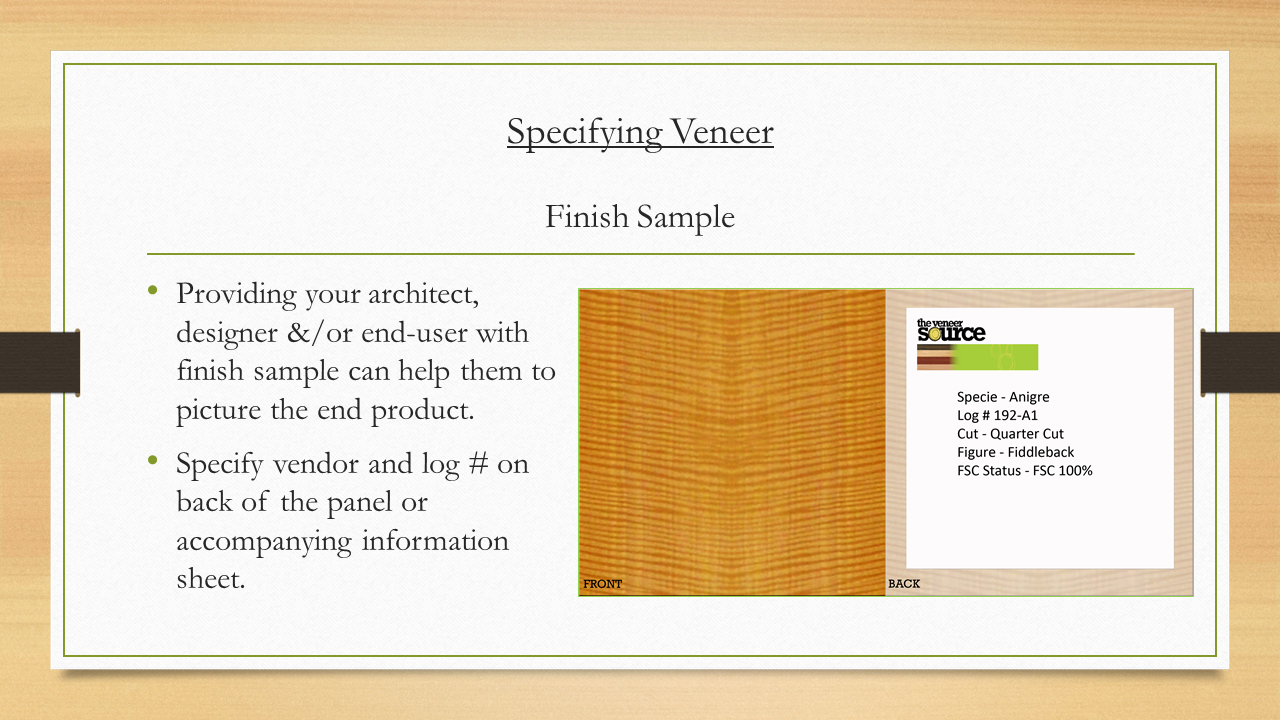

TVS provides clients with "Type Samples" and/or photos as well as general species information to determine the species, cut and figure type that best suites your needs. We are more than happy to set up appointments with your firm to present options in person.

TVS will help you identify specific logs in the desired species through log specific photos, tallies and "Live Samples". If desired TVS can set-up a showing for you and/or your client to inspect the veneer in person.

Once the perfect fit is decided upon, you can specify the log for your project with an intent to purchase or by pre-purchasing the material.

Would you like to learn more about the many facets of veneer and the specification process?

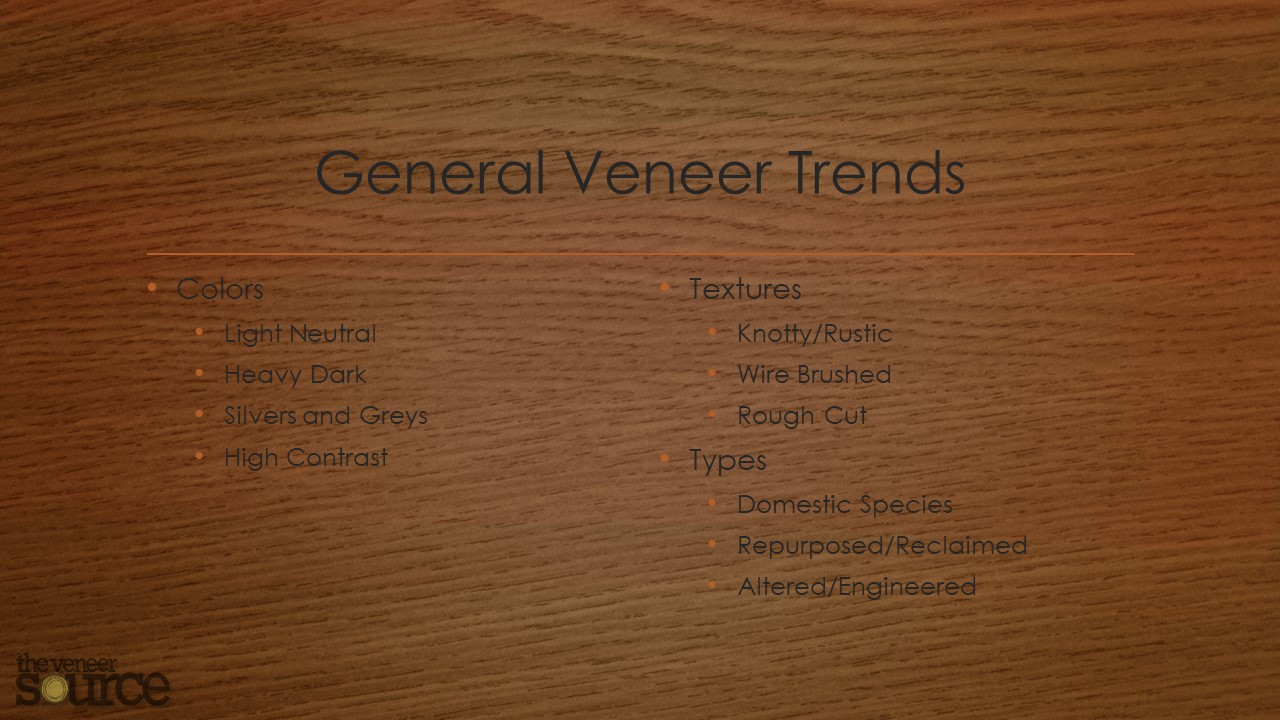

View our "2018 Veneer Trends" presentation below

View our Architectural Veneer presentation below

Leadership in Energy and Environmental Design (LEED) is a third-party certification program. It is a nationally accepted organization for design, operation and construction of high performance green buildings. This ensures the buildings are environmentally compatible, provide a healthy work environment and are profitable. LEED's "Green Building Rating System™" attempts to certify and push the advancement of a planet-wide implementation of green building and development practices. Their goal is to accomplish this through the creation of a universal set of tools and performance standards.

LEED has certification and performance standards for divisions of building such as "New Construction," which is designed to foster the growth of and distinguish commercial projects and new institutions conforming to green building practices at the highest levels; for "Existing Buildings," LEED has instituted guidelines for maintenance and ongoing operation, which gives building owners and operators a standard of environmental excellence to reach for; there is even a set of standards for "Schools," which serves to put special guidelines in place for the potentially unique nature of the concerns facing school spaces. In addition to these three divisions, there are also standards for "Commercial Interiors," "Core and Shell," "Retail," "Healthcare," "Homes" and "Neighborhood Development."

2.2 million + square feet is LEED certified every day with more than 92,000 projects using LEED.

Flexible; LEED works for all building types anywhere. LEED is in over 165 countries and territories.

Sustainable; LEED buildings save energy, water, resources, generate less waste and support human health.

Value; LEED buildings attract tenants, cost less to operate and boost employee productivity and retention.

LEED Standards

MR 7: Certified Materials

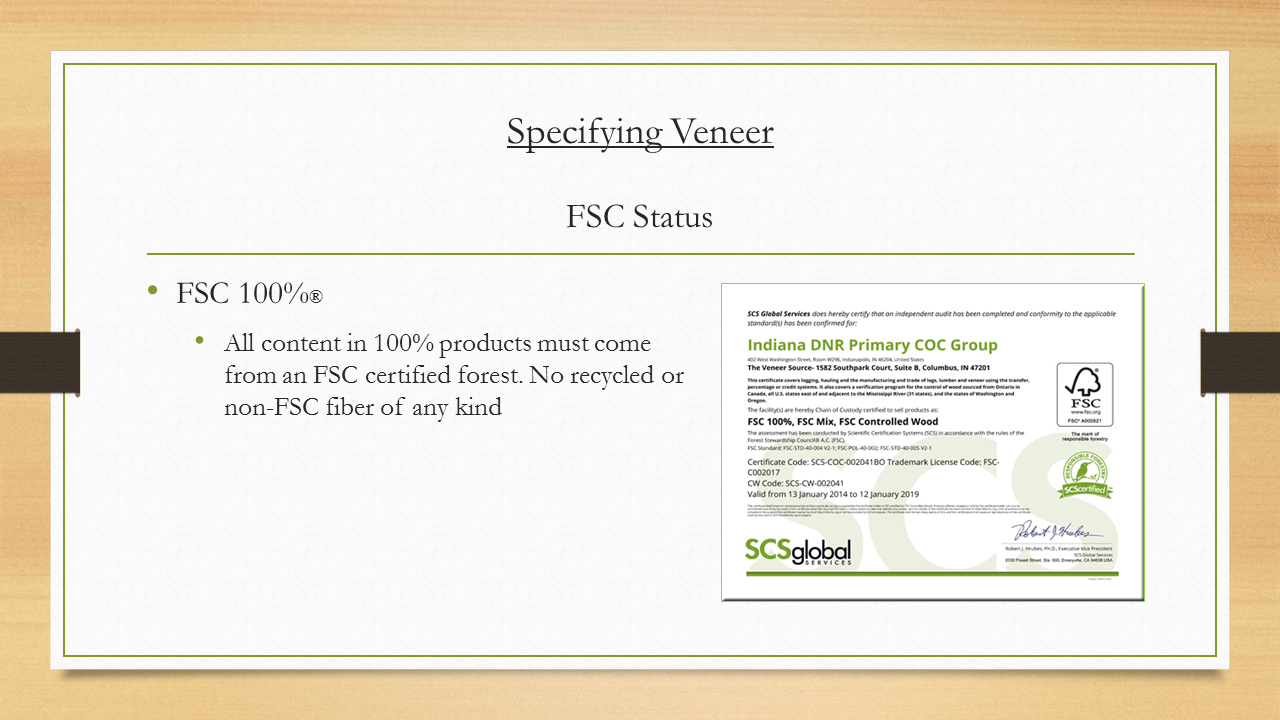

Certified Materials: LEED Credit MR 7 grants credits only for use of Forest Stewardship Council (FSC) certified end wood products. Other credible certification programs are the Sustainable Forestry Initiative (SFI), American Tree Farm System, CFC and PEFC.

MR Credit 4.1: Recycled Content: 10% (post-consumer + ½ pre-consumer) Intent: Increase demand for building products that incorporate recycled content materials, thereby reducing impacts resulting from extraction and processing of virgin materials.

Requirements: Use materials with recycled content such that the sum of post-consumer recycled content plus one-half of the pre-consumer content constitutes at least 10% (based on cost) of the total value of the materials in the project. The recycled content value of a material assembly shall be determined by weight. The recycled fraction of the assembly is then multiplied by the cost of assembly to determine the recycled content value.

MR Credit 4.2: Recycled Content: 20% (post-consumer + ½ pre-consumer)

Intent: Increase demand for building products that incorporate recycled content materials, thereby reducing the impacts resulting from extraction and processing of virgin materials.

Requirements: Use materials with recycled content such that the sum of post-consumer recycled content plus one-half of the pre-consumer content constitutes an additional 10% beyond MR Credit 4.1 (total of 20%, based on cost) of the total value of the materials in the project. The recycled content value of a material assembly shall be determined by weight. The recycled fraction of the assembly is then multiplied by the cost of assembly to determine the recycled content value.

MR Credit 5.1: Regional Materials: 10% Extracted, Processed & Manufactured Regionally

Intent: Increase demand for building materials and products that are extracted and manufactured within the region, thereby supporting the use of indigenous resources and reducing the environmental impacts resulting from transportation.

Requirements: Use building materials or products that have been extracted, harvested or recovered, as well as manufactured, within 500 miles of the project site for a minimum of 10% (based on cost) of the total materials value. If only a fraction of a product or material is extracted/harvested/recovered and manufactured locally, then only that percentage (by weight) shall contribute to the regional value.

MR Credit 5.2: Regional Materials: 20% Extracted, Processed & Manufactured Regionally

Intent: Increase demand for building materials and products that are extracted and manufactured within the region, thereby supporting the use of indigenous resources and reducing the environmental impacts resulting from transportation.

Requirements: Use building materials or products that have been extracted, harvested or recovered, as well as manufactured, within 500 miles of the project site for an additional 10% beyond MR Credit 5.1 (total of 20%, based on cost) of the total materials value. If only a fraction of a product or material is extracted/harvested/ recovered and manufactured locally, then only that percentage (by weight) shall contribute to the regional value.

EQ Credit 4.4: Low-Emitting Materials: Composite Wood & Agrifiber Product

Intent: Reduce the quantity of indoor air contaminants that are odorous, irritating and/or harmful to the comfort and well-being of installers and occupants.

Requirements: Composite wood and agrifiber products used on the interior of the building (defined as inside of the weatherproofing system) shall contain no added urea-formaldehyde resins. Laminating adhesives used to fabricate on-site and shop-applied composite wood and agrifiber assemblies shall contain no added urea-formaldehyde resins.

Composite wood and agrifiber products are defined as: particleboard, medium density fiberboard (MDF), plywood, wheat board, strawboard, panel substrates and door cores. Materials considered fit-out, furniture and equipment (FF&E) are not considered base building elements and are not included.